Serpentine Saw PLC Control System

Customer: A local company is an industry authority on standard and customized stainless steel tube fittings and machine parts. For over three decades this business served the dairy industry, food and beverage manufacturers, the bio-pharmaceutical industry, and more. They have the equipment, processes, and highly experienced personnel to ensure engineer specifications and standards are met or exceeded.

Customer: A local company is an industry authority on standard and customized stainless steel tube fittings and machine parts. For over three decades this business served the dairy industry, food and beverage manufacturers, the bio-pharmaceutical industry, and more. They have the equipment, processes, and highly experienced personnel to ensure engineer specifications and standards are met or exceeded.

Project Scope: Industrial Automation was asked to design, program, and install a new PLC control system that enhances the performance and control capabilities of the existing serpentine stainless tube cutting machine.

Venture purchased and installed three used 1,000 ton partial revolution punch presses and various stock handling equipment to be used in creating three new production lines at their facility. The presses were in good mechanical condition but the electrical controls were outdated, unsafe, and not suited for modern automated dies. Industrial Automation was given the task of replacing the electrical control systems and integrating the punch press controls with other production line stock handling equipment. This total control integration would create three fully automated production lines.

Project Design: The Serpentine tube saw has evolved since its first development with all hydraulic and pneumatic actuators to include a servo actuated saw positioning system. The originally system was very difficult to use. Set up for product changes could take hours and required a PC for programming the many set up variables. Crashes and broken blades were common.

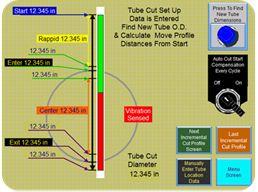

Industrial Automation designed, constructed, and programmed a new Allen Bradley control system that automatically detects the pipe inner and outer wall diameter positions using vibration analysis. The control system will automatically generate a new pipe cut profile based upon pre assigned trajectory variables. The new control will alter the saw trajectory on the fly to compensate for blade wear as well as tube wall material thickness variances during a cut cycle. This new control system incorporates a Compact Logix processor with Ethernet IP communications to control an Allen Bradley Kinetics servo motor drive that also employs Ethernet IP communications.

Ethernet communication modules are installed in each of two existing Power Flex 40 saw blade motor drives. This allows us to precisely monitor and control all saw motor drive parameters. Current feedback from the saw motors is then used to tweak the blade feed rate. The Touch screen is also improved and is connected to the control system via the machine’s dedicated Ethernet network. A covered Ethernet port is mounted to the outside of the control enclosure.

This port allows safe connection to other equipment such as a PC or a plant PC server and possible remote monitoring or service via the web. A five port unmanaged Ethernet switch is installed to facilitate device Ethernet connections.

Project Results: As a result of all of these improvements the cutoff process is greatly enhanced. Set up for a new part is done automatically. The serpentine pipe cutting process is faster, the cut is cleaner, and saw blades last longer.