Scoop Inserter

Customer:

A packager of powdered products

Scope:

A packager of powdered products needed a way to automatically insert measuring scoops into the canisters filled with powder.

Design:

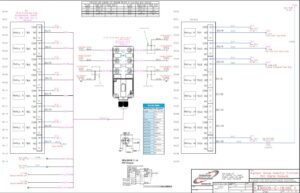

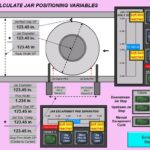

The design utilized 2 feeder bowls to account for a broad array of different scoop diameters and handle sizes. One feeder bowl at a time is connected to the machine due to space constraints. A trap door escapement mechanism and air nozzles are used for alignment assistance. A conveyor was integrated to index canisters into position under the trapdoor escapement. The X-axis side rails and Y-axis escapement pins on the conveyor were automated to account for the different canister sizes while keeping the center of the canister under the Z-axis pick and place. The Z-Axis pick and place is made up with a LinMot linear motor & drive, “H” guide assembly, an air operated brake, vacuum generators with blowoff, custom end of arm tooling, and a custom end of arm tool with suction cups. The Z-axis pick and place can be programmed for variable “Home”, “Pick”, and “Place” positions along with vacuum and blow off positions. The Z-Axis has 1000mm of travel with speeds of up to 2500mm per second. The design goal was to have < 1 second total cycle time between canisters in order to meet 40 canisters per minute. The LinMot linear actuator made this possible. The control consists of an Allen Bradley Compact Logix controller along with a 19” Cmore color touch screen.

The touch screen allows the operator to select a container dimension and a scoop part number from a list. These variables setup the Z-axis pick & place coordinates, move the conveyor X-axis side guides, and align the Y-axis escapement pins into the appropriate positions. Selected scoops are then loaded into the feeder bowl hopper. Sorted scoops are presented to a rail with sensors, a trap door escapement mechanism, and air nozzles for alignment assistance. The conveyor will bring a container into position under the Z-axis pick and place end of arm tool. The escapement pins will trap the container, then the Z-axis will move to a scoop pick position at the rail escapement and start vacuum. Once vacuum is established, the trap door escapement will open, the Z-axis will move down to the “place” position, vacuum will terminate and a blowoff will be initiated. Once vacuum is terminated, the Z-axis will retract to “home” position, the escapement pins will operate to bring in another container for the next placement.

The touch screen allows the operator to select a container dimension and a scoop part number from a list. These variables setup the Z-axis pick & place coordinates, move the conveyor X-axis side guides, and align the Y-axis escapement pins into the appropriate positions. Selected scoops are then loaded into the feeder bowl hopper. Sorted scoops are presented to a rail with sensors, a trap door escapement mechanism, and air nozzles for alignment assistance. The conveyor will bring a container into position under the Z-axis pick and place end of arm tool. The escapement pins will trap the container, then the Z-axis will move to a scoop pick position at the rail escapement and start vacuum. Once vacuum is established, the trap door escapement will open, the Z-axis will move down to the “place” position, vacuum will terminate and a blowoff will be initiated. Once vacuum is terminated, the Z-axis will retract to “home” position, the escapement pins will operate to bring in another container for the next placement.

Results:

The Customer now has an automated scoop inserter that eliminates a highly repetitive and mundane task.