High Voltage Power Supply System Integration

Company:

Electronic components manufacturer located in North America, Europe, and Asia.

Project Scope:

Industrial Automation was contracted to integrate a PLC and HMI with their High Voltage Power Supply testing system. The HMI and the PLC allowed the operators to manipulate voltage and current values as well as the time allowed for each testing cycle. The main operation had 12 sequences that were to happen in specific order.

Project Integration and Design:

Industrial Automation was able to work via Email due to the location of the company. Industrial Automation was provided with documents stating the process and each sequence that was to take  place. Industrial Automation programmed the HMI with multiple screens of parameters such as high voltage settings, voltage and current ramp up and ramp down times, as well as offsets to the voltage and current values. The HMI also included a running screen which displayed a countdown time, sequence status, analog output displays, status bits, and value indicators to display the set parameters and the present values.

place. Industrial Automation programmed the HMI with multiple screens of parameters such as high voltage settings, voltage and current ramp up and ramp down times, as well as offsets to the voltage and current values. The HMI also included a running screen which displayed a countdown time, sequence status, analog output displays, status bits, and value indicators to display the set parameters and the present values.

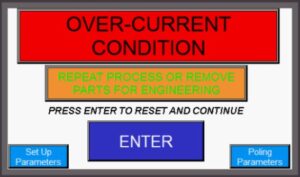

The Click PLC used a 0-10VDC analog output to control the voltage and current being applied to the operation. There were two inputs, one used for cycle completion and another used as an overcurrent monitor which when sensed, would ramp down and shut off the operation to allow safe inspection. The outputs on the PLC were used to control the components used within the poling system operation. The PLC program relied on mathematical and timing functions to follow the specific order of operations required in the poling sequence.

Results:

With the PLC and HMI integration with the poling system, operators have the ability to easily take control of their system by having the capability to manipulate the operation from every aspect.