Creamery SCADA

Customer:

Creamery

Scope:

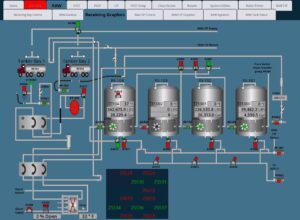

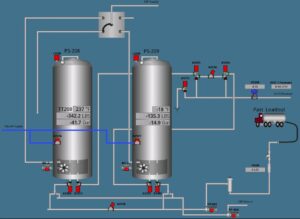

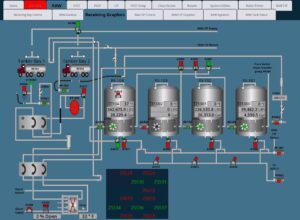

Production HMI/ SCADA was built on Rockwell’s FactoryTalk View SE platform running on Windows XP/ 7 OS machines. The refrigeration HMI/ SCADA application was built on Parker’s Interact X platform running on a XP OS machine. Windows security updates and patches were no longer available so a system update or re-write was required to have a secure and up to date HMI/ SCADA system. Licensing and the update process with the Factorytalk View platform and Interact X were costly, time consuming, and did not offer all the same features found in the other platforms. One of the other production facilities was already using Ignition, by Inductive Automation, so they decided to make this their preferred HMI/ SCADA platform.

The creamery had 4 clients running a production application and 1 client running a refrigeration application. Each of these clients ran on a dedicated desktop, with a copy of the appropriate application and licensing. The client application was displayed on the floor, remotely, on a large industrial touch screen.

No historical data logging or trending was utilized. All required data arrays including CIP recipes and users were stored in the PLC.

Design:

A new server was installed for the Ignition gateway along with a connection to an existing MS SQL instance for data storage. Connections were made to the production and refrigeration PLC’s. Each of the 50+ screens were decoded and re-assembled into the new Ignition platform. Pages were updated, condensed, and simplified in order to meet current production needs and usability. New screens were created for a production user table and CIP recipe update. Both of these sections were designed to interface with the SQL database in lieu of PLC tag arrays. Users were authenticated against active directory for security and a streamlined design.

A new server was installed for the Ignition gateway along with a connection to an existing MS SQL instance for data storage. Connections were made to the production and refrigeration PLC’s. Each of the 50+ screens were decoded and re-assembled into the new Ignition platform. Pages were updated, condensed, and simplified in order to meet current production needs and usability. New screens were created for a production user table and CIP recipe update. Both of these sections were designed to interface with the SQL database in lieu of PLC tag arrays. Users were authenticated against active directory for security and a streamlined design.

Results:

The facility now has a unified SCADA/ HMI platform with unlimited clients, tags, and device connections. This new platform is running on secure operating systems throughout the facility. Client applications can be easily updated thru an Ignition gateway launched designer. Data is now securely stored and backed up to a database where it can be easily updated and trended. The Ignition framework will allow the facility to expand its ability to increase production visibility in order to make a more quality product and be more efficient.