Generator Control Systems

Customer: A local University has a power generation center, on a campus in La Crosse, Wisconsin, that provides steam power for campus facilities.

Customer: A local University has a power generation center, on a campus in La Crosse, Wisconsin, that provides steam power for campus facilities.

Project Scope: The Power Generation Center provides high and low pressure steam to heat the dormitories at the University and for campus commissary cooking needs. Excess high pressure steam is routed to two turbine powered generators to recover much of the excess energy as electricity. Low pressure exhaust steam from the generators is directed to other building heating equipment. The OEM installed PLCs that control the generators and steam regulation became obsolete. Replacement parts were unavailable and support was difficult to find. Industrial Automation was hired to update and replace the aged and failing control system.

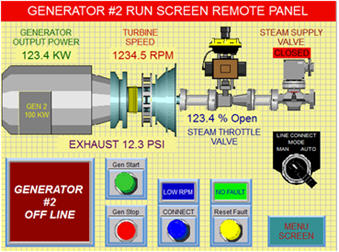

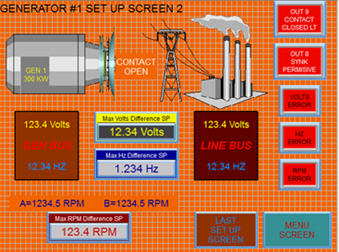

Project Design: Each of the two generators was refitted by employing an Allen Bradley Compact Logix 1769-L23 PLC and an 8” color touch screen. Each of the touch screens is capable of communicating with either generator control system for operator control redundancy. Each touch screen includes a graphic “running” screen, set up screen, service screen, and a power generated history screen for both generators. The two PLCs also share power production and steam usage data with a building management system for viewing at multiple locations on campus by maintenance, supervisors, and students.

Project Design: Each of the two generators was refitted by employing an Allen Bradley Compact Logix 1769-L23 PLC and an 8” color touch screen. Each of the touch screens is capable of communicating with either generator control system for operator control redundancy. Each touch screen includes a graphic “running” screen, set up screen, service screen, and a power generated history screen for both generators. The two PLCs also share power production and steam usage data with a building management system for viewing at multiple locations on campus by maintenance, supervisors, and students.

Project Results: The new control system now controls the turbine supply steam precisely. The generators now start up dependably and after a programmed idle speed warm up, synchronize to line voltage and go on line very quickly. Once on line, the generator power produced is maximized while the exhaust pressure (low pressure steam) is precisely controlled for use in other building requirements.

Project Results: The new control system now controls the turbine supply steam precisely. The generators now start up dependably and after a programmed idle speed warm up, synchronize to line voltage and go on line very quickly. Once on line, the generator power produced is maximized while the exhaust pressure (low pressure steam) is precisely controlled for use in other building requirements.