Foundry Sand Control System Retrofit

Customer: State-of-the-art metal casting facility

Customer: State-of-the-art metal casting facility

The original automated foundry green sand preparation, sand distribution, and sand reclaiming systems consisted of numerous independently controlled islands of automation. Each of the various SLC500 process controllers were loosely coupled by digital go / no-go I/O signals from one control system location to the next. Batched sand quality was not consistent, would sometimes be unusable, or a system would halt for reasons that were difficult to determine.

Project Scope: The foundry needed to improve the quality, predictability, and reliability of the sand batching systems. They also wanted to be able to view all process conditions and control all commonly adjusted sand quality and distribution variables for the entire sand preparation system at multiple locations in the plant. A SCADA system with a database connection was needed for system control, data archiving, compactability distribution, and mull trending. To help make the batched sand more consistent, the green sand weighing, bond weighing, and water delivery accuracy needed to be improved. The muller mixing motor power usage needed to be monitored and precisely controlled to reduce energy consumption.

Project Scope: The foundry needed to improve the quality, predictability, and reliability of the sand batching systems. They also wanted to be able to view all process conditions and control all commonly adjusted sand quality and distribution variables for the entire sand preparation system at multiple locations in the plant. A SCADA system with a database connection was needed for system control, data archiving, compactability distribution, and mull trending. To help make the batched sand more consistent, the green sand weighing, bond weighing, and water delivery accuracy needed to be improved. The muller mixing motor power usage needed to be monitored and precisely controlled to reduce energy consumption.

Project Design: Industrial Automation designed, programmed, and installed a new Compact Logix control system to replace the existing SLC500 system and improve the capabilities of the sand batching system. All existing DH+ remote communications were replaced with Ethernet IP communications. Ethernet IP communications were also added to several older SLC500 controlled systems that remained in service. A new PF525 VFD was installed to control the sand weigh hopper filling.

Project Design: Industrial Automation designed, programmed, and installed a new Compact Logix control system to replace the existing SLC500 system and improve the capabilities of the sand batching system. All existing DH+ remote communications were replaced with Ethernet IP communications. Ethernet IP communications were also added to several older SLC500 controlled systems that remained in service. A new PF525 VFD was installed to control the sand weigh hopper filling.  The air controlled bond weigh hopper filling was converted to an auger fill system also driven by a PF525 VFD. A new true power meter was added to closely monitor the power consumed by the muller mixer motor soft starter. Ignition SCADA software was installed on an existing server with a connection to an SQL database. One dedicated touchscreen PC with backup provision was mounted to the existing control panel. The sand system SCADA application is accessible to any client on the network with appropriate credentials. A VPN portal allows Industrial Automation to monitor, troubleshoot problems, and make program updates remotely.

The air controlled bond weigh hopper filling was converted to an auger fill system also driven by a PF525 VFD. A new true power meter was added to closely monitor the power consumed by the muller mixer motor soft starter. Ignition SCADA software was installed on an existing server with a connection to an SQL database. One dedicated touchscreen PC with backup provision was mounted to the existing control panel. The sand system SCADA application is accessible to any client on the network with appropriate credentials. A VPN portal allows Industrial Automation to monitor, troubleshoot problems, and make program updates remotely.

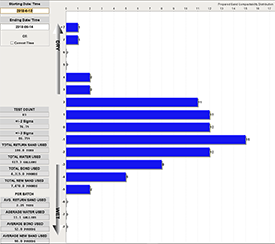

Project Results: Batch green sand weighing accuracy is greatly improved. A 4,500 lb. batch weigh hopper fill is usually within one or two pounds of set point. Bond weigh accuracy is also improved within a fraction of a pound of set point. Water add sequencing was changed to eliminate unpredictable water loss due to splashing on the muller walls. The mulling completion determination is now based upon total power consumed and the shape of the batch mixer power graph resulting in reduced mulling time and reduced energy consumption. Control and visualization of the automated sand testing lab system was improved. he SCADA system graphically displays batching and sand distribution equipment status and allows for the set up and control of these systems. In addition, the SCADA system displays historical sand compactability distribution, mixing muller trending, and sand lab test data. The SCADA system also allows the operator to navigate to any sub system to see the status and make changes to these systems (based on user credentials). The Ignition SCADA system also communicates with several other older SLC500 control systems that currently still control the sand reclaim and black water systems. Limited control and monitoring of these systems was also added to the touchscreens.

Project Results: Batch green sand weighing accuracy is greatly improved. A 4,500 lb. batch weigh hopper fill is usually within one or two pounds of set point. Bond weigh accuracy is also improved within a fraction of a pound of set point. Water add sequencing was changed to eliminate unpredictable water loss due to splashing on the muller walls. The mulling completion determination is now based upon total power consumed and the shape of the batch mixer power graph resulting in reduced mulling time and reduced energy consumption. Control and visualization of the automated sand testing lab system was improved. he SCADA system graphically displays batching and sand distribution equipment status and allows for the set up and control of these systems. In addition, the SCADA system displays historical sand compactability distribution, mixing muller trending, and sand lab test data. The SCADA system also allows the operator to navigate to any sub system to see the status and make changes to these systems (based on user credentials). The Ignition SCADA system also communicates with several other older SLC500 control systems that currently still control the sand reclaim and black water systems. Limited control and monitoring of these systems was also added to the touchscreens.