Crouton Conveyor Case Inspection and Automation

Customer: Local Industrial Bakery

Customer: Local Industrial Bakery

Project Scope: The manually packaged crouton case box filling line was inefficient and often halted. The line was built on a single common empty and filled case box conveyor system. The entire filling line was often halted due to any problem in any one of the four filling stations that fed into this single conveyor. The delays were mainly caused by problems in either of the two most downstream filling stations. The owner wanted to improve the box filling throughput by a dual conveyor system that includes multiple right angle transfer units.

A second mode was used for bulk filling boxes. An operator would open and close a crouton filling gate manually while observing a scale to achieve the proper fill weight in each box. The new conveyors control system will automatically fill and weigh the bulk boxes.

Project Design: Industrial Automation was asked to design, construct, and install a new dual conveyor system to replace the single conveyor that now supplies boxes to the two most downstream of four crouton filling stations (3 and 4). An intelligent automated controller will inspect the case boxes at various points on the new conveyors using photo eyes. Filled boxes will be diverted around the downstream filling stations, while boxes needing product will be staged ahead of the appropriate fill station. When an operator has completed adding bags of croutons to the case box, he will press a foot switch and the filled or partially filled box will continue downstream to either the next fill station or to the exit conveyor as is appropriate.

Project Design: Industrial Automation was asked to design, construct, and install a new dual conveyor system to replace the single conveyor that now supplies boxes to the two most downstream of four crouton filling stations (3 and 4). An intelligent automated controller will inspect the case boxes at various points on the new conveyors using photo eyes. Filled boxes will be diverted around the downstream filling stations, while boxes needing product will be staged ahead of the appropriate fill station. When an operator has completed adding bags of croutons to the case box, he will press a foot switch and the filled or partially filled box will continue downstream to either the next fill station or to the exit conveyor as is appropriate.

The bulk filling process will also be automated and incorporated into the dual conveyor control system by adding a PAC (Programmable Automation Control) controlled weigh scale that supports Ethernet communications along with a gate mechanism. The new bulk weight measuring system will be installed in a four foot removable conveyor section at the exit end of the new conveyor line. When the bulk fill is not used, the crouton hopper and weigh scale conveyor section will be removed from the production line. A new dual four foot conveyor section will then be installed in the space left by the bulk filling equipment. The new manual fill dual four foot conveyor section will include a right angle transfer system at its exit end.

The bulk filling process will also be automated and incorporated into the dual conveyor control system by adding a PAC (Programmable Automation Control) controlled weigh scale that supports Ethernet communications along with a gate mechanism. The new bulk weight measuring system will be installed in a four foot removable conveyor section at the exit end of the new conveyor line. When the bulk fill is not used, the crouton hopper and weigh scale conveyor section will be removed from the production line. A new dual four foot conveyor section will then be installed in the space left by the bulk filling equipment. The new manual fill dual four foot conveyor section will include a right angle transfer system at its exit end.

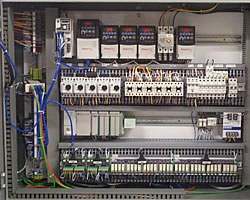

The new belt driven roller conveyors and right angle transfer units are manufactured by Hytrol Conveyor Co. The automation controller is an Allen Bradley Compact Logix PAC system. The operator interface touch screen is an Automation Direct 12 inch color unit. The new control system will include new Allen Bradley Power Flex 40 variable frequency drives to control the speeds of the new conveyor motors and the motors in the existing two conveyor sections that will remain in service. The conveyor movable box stops, right angle transfer lifts, pneumatic control, and air prep equipment is manufactured by SMC. Photo eyes and laser distance sensors by IFM Effector to determine the box fill levels are included. The new Allen Bradley Control Logix system will incorporate an internal Ethernet network for enhanced control communications with the systems motor drives, touch screen, and other installed or future intelligent devices.

The new belt driven roller conveyors and right angle transfer units are manufactured by Hytrol Conveyor Co. The automation controller is an Allen Bradley Compact Logix PAC system. The operator interface touch screen is an Automation Direct 12 inch color unit. The new control system will include new Allen Bradley Power Flex 40 variable frequency drives to control the speeds of the new conveyor motors and the motors in the existing two conveyor sections that will remain in service. The conveyor movable box stops, right angle transfer lifts, pneumatic control, and air prep equipment is manufactured by SMC. Photo eyes and laser distance sensors by IFM Effector to determine the box fill levels are included. The new Allen Bradley Control Logix system will incorporate an internal Ethernet network for enhanced control communications with the systems motor drives, touch screen, and other installed or future intelligent devices.

Project Results: The new control, automation equipment and conveyors on the box filling line allow for a much less restricted product flow and greatly increased product through put. The automated bulk filling automation allows for an operator to be utilized in other areas of the production line.